The Pee Empro Group is driven by a range of core strengths, foremost among them being its fully vertically integrated manufacturing structure for woven garments. The Group operates a comprehensive in-house ecosystem that encompasses every critical stage of production, beginning with fabric processing and extending through to the manufacture of finished garments. This integrated setup includes a state-of-the-art dyeing and printing facility, Creative Dyeing & Printing Mills Pvt. Ltd., a specialized Schiffli embroidery unit, Hemla Embroidery Mills Pvt. Ltd., and approximately 500,000 square feet of garment manufacturing facilities equipped with modern machinery and advanced production systems. All processes—from fabric dyeing, printing, and embroidery to cutting, sewing, finishing, and packing—are managed under a single, unified management structure. By maintaining complete control over the entire value chain, the Pee Empro Group ensures consistent product quality, strict adherence to international standards, optimized lead times, and reliable on-time deliveries. This vertical integration also enables greater design flexibility, enhanced customization capabilities, and a broader range of fabric and garment options, allowing customers to select from a diverse and innovative product portfolio. As a result, the Group is able to respond efficiently to evolving market demands while delivering superior value and long-term partnership to its global clientele.

Our Strength

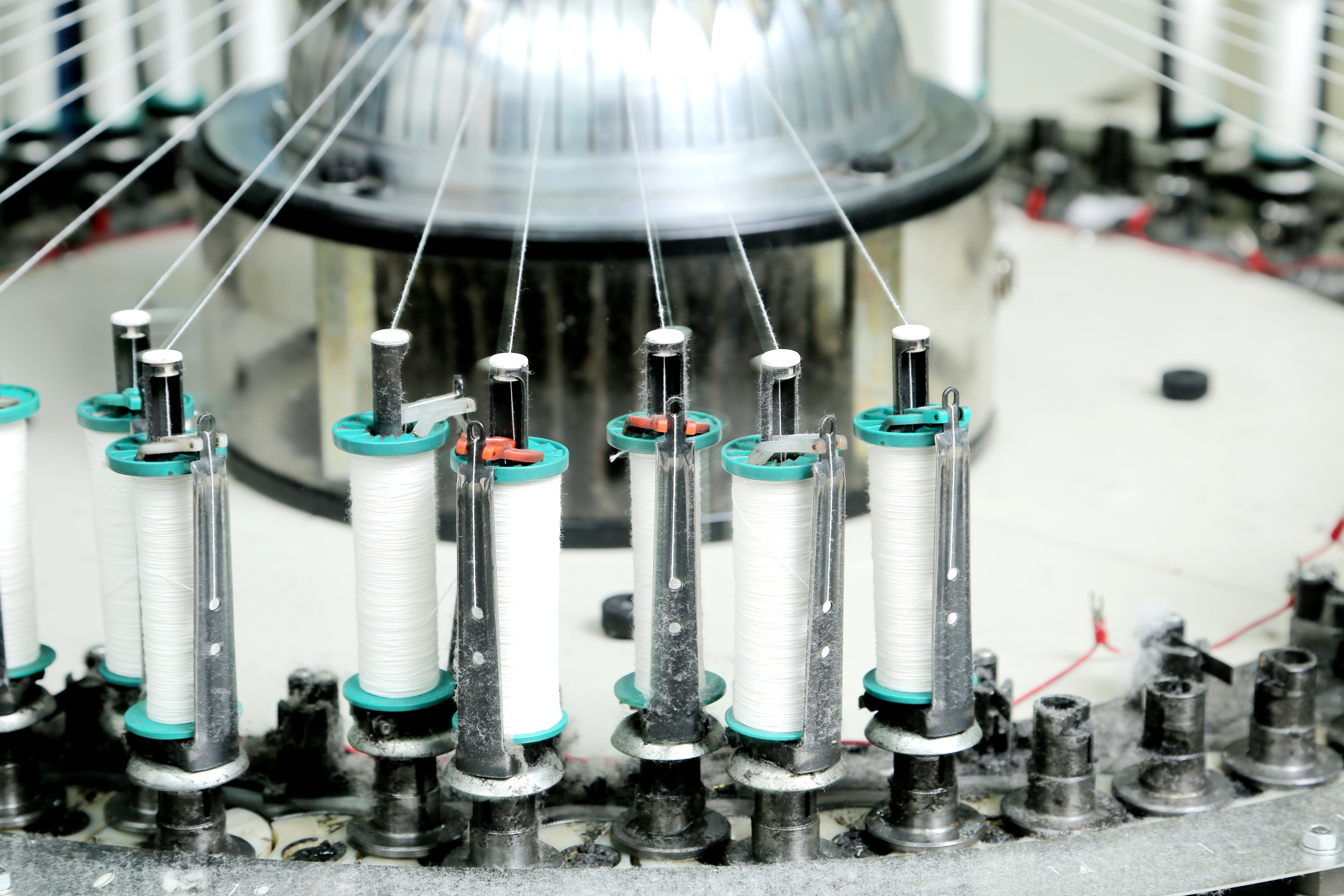

Pee Empro’s manufacturing excellence is built on robust infrastructure, advanced technology, and a strong commitment to quality. The Group operates approximately 3,000 single-needle sewing machines, supported by state-of-the-art CAD and CAM systems, enabling high levels of precision, efficiency, and consistency across all stages of garment production. In addition, Pee Empro is equipped with 30 Tajima multi-head computerized embroidery machines, allowing the execution of intricate embroidery designs while maintaining superior accuracy, uniformity, and scalability. Our advanced embroidery capabilities provide enhanced design flexibility and support a wide range of customer-specific requirements.To ensure complete control over product quality, Pee Empro maintains fully integrated washing facilities and in-house testing laboratories, enabling continuous monitoring of fabric and garment performance against international quality standards.

These facilities ensure that every product delivered meets stringent quality, durability, and compliance expectations.With a production capacity of approximately 1,000,000 garments per month, Pee Empro consistently delivers high-volume orders while maintaining an exceptionally low rejection rate of approximately 0.5%, reflecting our strong quality systems and process controls. The Group’s operational strength is further reinforced by an annual turnover exceeding USD 95 million, underscoring financial stability, scalability, and long-term reliability as a global sourcing partner.